Find 840 Glazed Tile Steel Roofing Machine, Steel Roofing Machine, Corrugated Sheet Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T,D/P,Western Union,OA |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 40 Days |

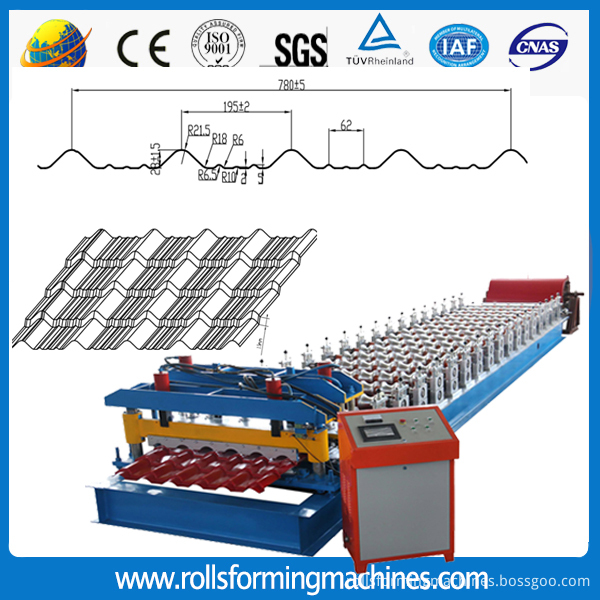

Model No.: ZT-004

840 glazed tile roll forming machine, the feeding width is1000mm.

Product features of Glazed tile forming machine:The glazed tile produced by this roll forming machine is beautiful in appearance, elegant in style and unique in design.Product application of Glazed tile forming machine:The products of this forming machine are widely used in such buildings as villa, vacation villages, factories, hotels etc.

The archaize glazed tile through the roll into the stamping forming of with nice appearance, of primitive simplicity and elegant, elegant modelling chic, grade noble, etc. It can be used in the garden type factory, scenic spots, pavilions, hotel villa, the exhibition hall, the resort, the family, as well as building and outdoor decoration.

1.the dimension of decoiler:860mm*1450mm*1124mm(Length*width*height)

2.The max speed:12m/min

3.The thickness of steel: 0.5-0.6mm

4.The width of raw material:1000mm

5.The effective width :840mm tolerance ±1mm

6.The wave height:24mm tolerence 24-0.5mm

7.Roller steps: 13

8.The dimension of the machine:8268mm*1486mm*897mm

9.The dimension of pressing machine:477mm*1380mm*837mm

10.Main motor power:3.7KW

11.Roller material: 45#steel rolling chromium thickness:0.05mm

12.Diameter of shaft:70mm

13.Cycloid reducer :BWD22-71-3KW

14.Hydraulic pump: 4 kw

15. Imported inverter

16. Computer :imported PLC

17.Text screen

18.The whole machine including: main roll forming machine,hydraulic oil pump,decoiler,

Hydraulic cutter, computer control system,runout table.

840 glazed tile roll die forming of antique glazed tile roll forming machine has good appearance, of primitive simplicity and elegant, elegant chic modelling, such characteristics as high grade, can be widely used in factories, tourist scenic spot, pavilions, garden hotel, exhibition hall, resort villa, family and other buildings and outdoor decoration.

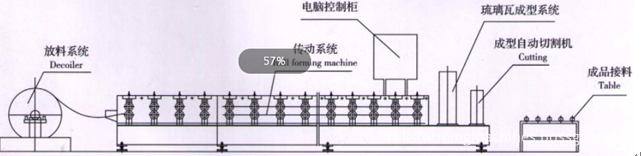

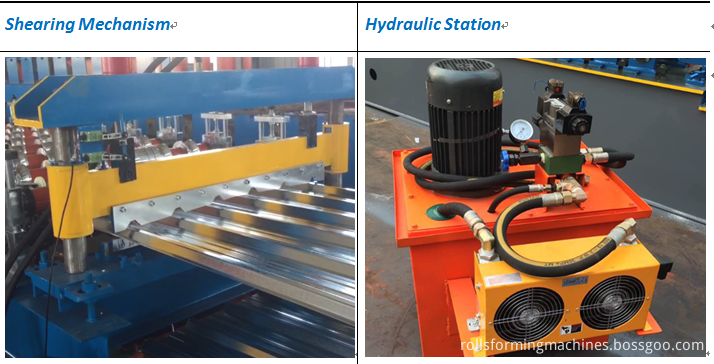

Glazed tile roll forming machine is mainly composed of feeding import platform, forming the host, punching mold type device, forming cutting device, hydraulic station, computer control system and so on several parts. Optional configuration has ordinary hydraulic feeding machine, automatic feeding machine, cut machine, finished product bracket, etc.

The profess flow if this machine is as below:

Manual decoiler→ Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

Here is some detailed specifications of this steel roof roll forming machine:

configurations manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table Material Raw material Galvanized Thickness 0.2-0.8 Manual Uncoiler Coil inner diameter 450-550 mm Max coil out diameter 1300 -1600 mm Max coil width 1250 mm Carrying capacity 5 T Entry Beach Put the raw material (steel plate) through the beach to manufacture and process it can guarantee that the products are neat, parallel and everything is uniformity Please refer to the equipment regulation to know the function of locate dam board. Main machine Forming steps 10 rollers Shaft diameter 60mm Design type Pillar structure roller material GCr12MoV steel shaft material 40Cr steel Work speed 2-8 m/min Transport By gear Power of main machine 11kw Type of cutting Hydraulic Cutting tolerance ±1mm Cutter Gcr12 Cutter quantity 2 set Working pressure 40MPA Shearing Mechanism Feature Ensure stability, precision and cutting speed Function Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades Cr12 quenched Power supply hydraulic power Components It contains one set of blade, one hydraulic tank and one cutter machine. Hydraulic Station Power 3 kw Hydraulic oil 46# Components The system includes a set of hydraulic tank, a set of hydraulic oil pump, 2 hydraulic pipes. And 1 sets of electromagnetism valves. Electric Control System 1.Adopted PLC, frequency converter, Delta from Taiwan to ensure high speed with stability, precision and lifetime. If you need, we can change it other brand or little computer type for touching screen. Counter One counter gauges length, pulses, and decides length. Omron encoder for length measurement size: 7000×4200×1600 mm pneumatic system air pump (air force) User Hotels Feeding system automatically turns off after the steel shaft geared motors feed Motor power 2.2KW material storage units store the finished work material storage units by the geared motor can move around Motor power 2.2KW electronic control system industrial electrical control system automatically feeding blanking The stack material thickness max.300mm Other Spare part Weight About 8 ton Dimension 4500*1000*1400mm L x W x H Main body color As required Voltage 380v/50hz/3ph(or as required) Spare cutting blade One piece for profile Fuse 2 pieces Relay 2 pieces Travel switch 2 pieces Solenoid valve 1 pieces Terms of payment 1. Terms of payment: 30%T/T, Balance to be paid before shipping after inspection. 2. Delivery time: 40 days. Warranty and Training 1. Warranty: Support the technology all the life. And the machine broken because of quality, we can change the broken part for free within one year. 2. Training: If you come to our factory, we can teach you for free. If you need technician go foreign, the buyer need pay the cost for visa, hotel, ticket, food and others, and buyer need pay the technician USD 80/day for salary. There need one technician. Training time will be one week.

Please refer to below pictures of this glazed tile roll forming machine:

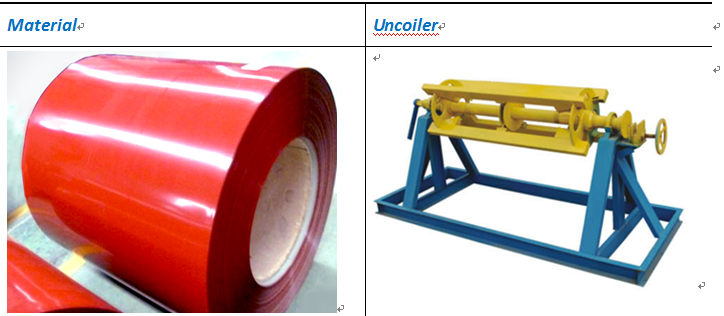

This steel roofing forming machine raw material is the steel coil, there are 3 types of the raw material: color steel coil, galvanize,steel aluminum zinc coil. About the color of the steel roof, usually, the red, blue,white,green and so on. you can choose any color of the steel coil you need.

There is a decoiler at beginning of the machine, to decoil the steel coil before feeding into the machine.

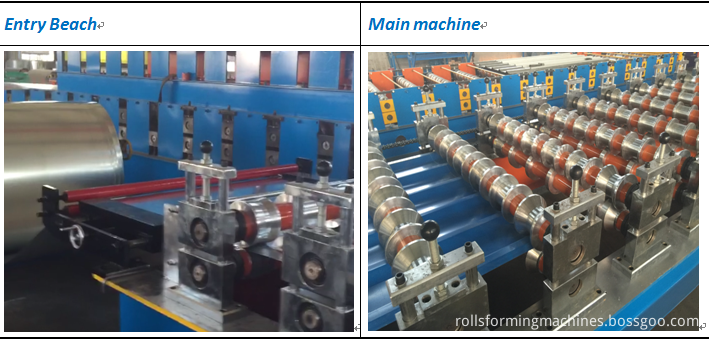

The entry beach is used to keep the coil be stable and straight through the feeding mouth into the roll forming rollers.

The main body is with designed rollers one station to ones station to roll forming the roofing sheet.

The shearing is to cut the glazed tile after the roof sheet been roll forming and be shaped by the shaping system.

The hydraulic stations is used to control the shearing system, to support the power of the energy of the cutting knives of the shearing system.

Ending:

Every glazed tile steel roofing forming machine is customized made according to customer's requirements, if you need this machine,please feel free contact us.

we can help you to design the machine, and get this machine with good service.

Contact us if you need more details on 840 Glazed Tile Steel Roofing Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Roofing Machine、Corrugated Sheet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Roofing Sheet Roll Forming Machine > Glazed Tile and Ridge Cap Roll Forming